Conventional cFI Instruments

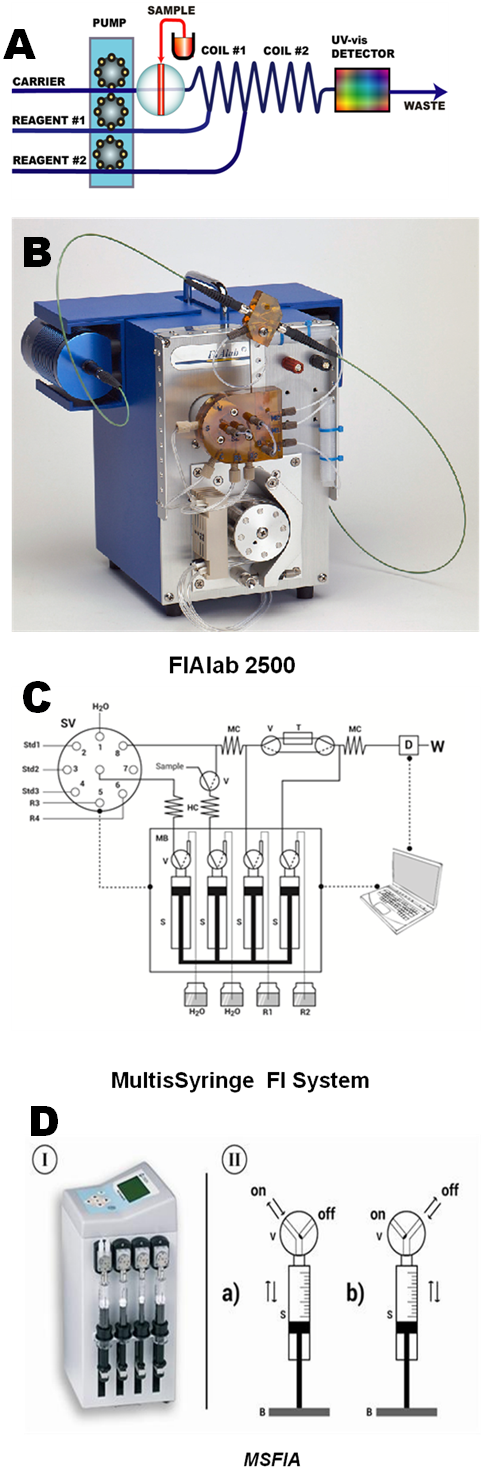

There are four principal components of any FI system: the pump, the injection valve the flow trough channel and the flow cell. Over the years this sequence of components forming the flow path remained unchanged (A), while advances in technology led to computerization of data collection, control of injection valve, functions of an auto sampler and in the case of more advanced systems, the flow rate of a pump.

The peristaltic pump based system FIAlabn 2500, operating in cFI mode, is an example of such design. The instrument (B) manufactured by FIAlab, is equipped with four channel pump, Tungsten light source, fiber optic cables, 1cm light path flow cell and Ocean Optics Spectrophotometer.

Replacing the peristaltic pump with a syringe pump was a logical extension of instrument development. Multisyringe Flow Injection Systems (MSFIA) were designed and manufactured by SCI Ware Systems (Cerdá 1999, 2002).The advantages of syringe pump are:

- resistance to corrosive chemicals

- precise control of liquid delivery

- capability of programmable flow, including stop flow FI for reaction rate measurement

- no need to replace peristaltic pump tubing

Multisyringe FI system, (C) is designed around the multisyringe pump (D). The pump is operated by a single drive that moves four syringes simultaneously, while the flow rates are selected by choice of syringe size. This design was adopted in order to simplify operation of the pump and of software design. Operation principles and applications of Multisyringe systems have recently been reviewed (Segundo 2006).

Cerdá V. et al., Talanta 50, 695 (1999) Miró M., Estela J.M., Cerdá V.,TRAC 21, 199 (2002)

1.4.2.